Steam Locomotive (page 10)

(Back to Page 9)

2/8/3

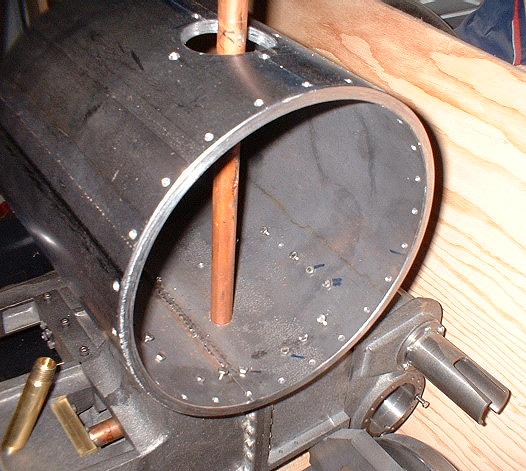

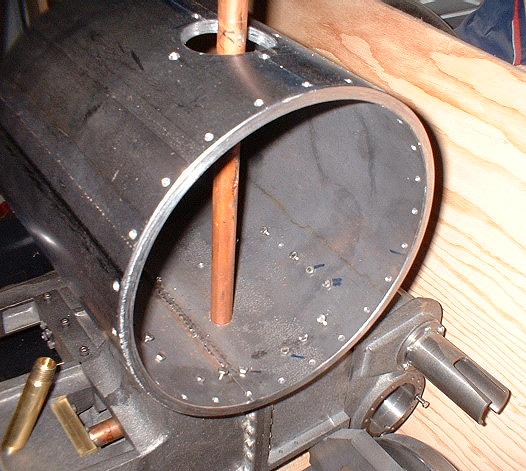

Another item one can work on at just about any time is the

smokebox. The first task is to cut the smokebox from a piece

of 8" schedule 40 pipe. The smokebox cover and door can be

cleaned up on the lathe. Then the task of drilling holes for

the smokestack, steam inlets, exhaust pipe, saddle, boiler ring,

cover mounting, hinges, and dogs can begin.

...

image 30: Smokebox, Cover, and Door, ready to drill and tap

...

...

image 31: Drilling Smokebox Cover

...

Here's what you do if you don't have an indexing head or a rotary

table. Use a lathe chuck. The index marks at the bottom of the

chuck were printed on the computer. The marks are in "put the

hole here" units.

...

image 32: Smokebox cover, door, and guard dogs

...

The smokebox door dog holes, drilled and tapped, the dogs are shown

holding the door on. Next we need to cut the 2" diameter hole on top

of the smokebox for the smokestack, and drill the four mounting holes

to hold the stack on. Then we need to drill the holes for the boiler

attach ring, and the hole in the bottom for the exhaust pipe.

...

image 33: Make sure the Smokebox is square

...

Before we can drill the holes for the bolts that will hold the smokebox

to the saddle, it is important to be sure the smokebox is square, both

vertically and laterally. A small error here will translate into a large

offset at the far end of the boiler.

...

image 34: Bolting the Smokebox to the Saddle

...

Once the correct position is determined, the mounting holes are drilled.

Next to be drilled -- holes for the two steam inlets, headlight mounting,

and inspection hole cover details.

(On to Page 11)

|