Railroads TiesWhat Do Real Railroads Do? Now let's translate to 1/8th scale.

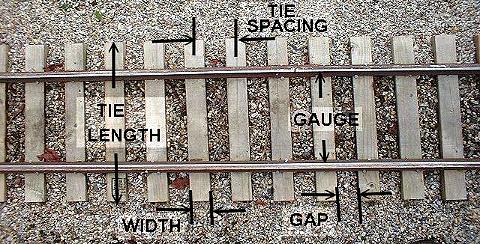

Tie LengthLonger ties can carry more load due to increased ground contact area. They tend to make a more stable track as they have more leverage. If we scale a prototype tie to 1/8th scale, we get 12.75". But if you cut up an 8 foot two-by-four into 12.75" pieces, you get 7 lengths, but end up with a good chunk of wood left over. So now let's divide 8 feet by 7 lengths, allowing for the saw cut you get 13.625" (or 13+5/8"). It's longer than 12.75", but longer is better. Tie WidthTie Economics 101Tie Gap and SpacingWhen I started laying track, I decided to use a tie width of 1+5/8" and a tie gap of 1+5/8". (This is a spacing of 3+1/2" minus the saw's kerf.) I used these dimensions because 1+5/8" is approximately what you get when you rip a piece of "two-by-four" in half, and it made sense at the time to make the gap equal to the tie width. The problem is -- no real railroad uses one-to-one width and gap. The gap is always wider. I was using more lumber than I needed, but worse yet, this practice makes it much more difficult to level and tamp ballast. Take a look at these two photos...

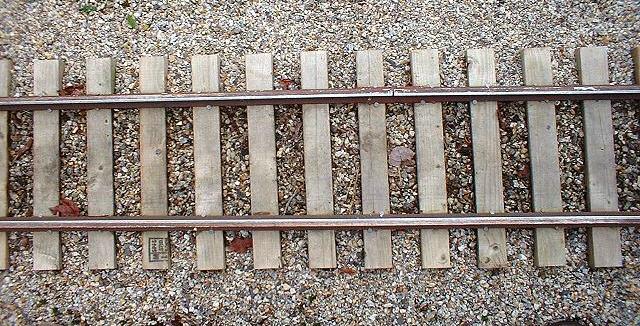

My entire main line is 3.5" spacing as pictured above. This requires 28 ties per 8 foot panel. It is tough to get the railroad pick between these ties.

My cutoff spur uses 4.05" spacing, as shown above. Not only does this require less wood, 24 ties per 8 foot panel, but I can get my tools between them. Most visitors don't even notice the difference until I point it out to them. Can you get by with even less ties? Yes you can! Tie Height or ThicknessCan ties be TOO tall?

Here's a private track I visited, where they use full width two-by-four lumber for ties. These ties are 3.5" tall. This practice is OK if that's what you want to do. From what I've heard the reason for using too-tall ties is "That's how it was always done". (Mid-South) This group was also having problems with the ties moving with the rail during expansion. That was most obvious at the rail gaps. And since the rail gaps were staggered, the ties would visibly skew at the joint. The extra height has no advantages (other than to save sawing). And if you have any soil movement at all, the tie now has more leverage against the rail/fastener connection. Also consider how much extra ballast is required to fill these ties, ballast that is not supporting anything. If they used stringers instead of double height ties, they would have used less wood and ballast and would have a stabler, smoother track without the drift problem. By the way, this was a fine team of hobbyists with an excellent track. Tie Treating

Copper NapthanateI started using this EPA blessed dock and post treatment on cheap lumber. Most of it washed off and now the untreated white pine is all that's left. The lumber was cheaper than CCA, But by the time one factors in the cost of the treatment, plus the time, there was no benefit to using it. Conclusion: Not Recommended

Copper-Chromium-Arsenic(alias CCA or the OLD deck lumber)So I started using CCA. It was a little pricier than the untreated, but I didn't have to buy or mess with copper napthanate. Then the local retailer was closing out their stocks of CCA, so I was bringing home double loads of this stuff. There are some safety issues with it.

Alkaline Copper Quaternary(alias ACQ, or the NEW deck lumber)Then the new deck lumber came out. It was considerably more costly than anything else below plastic. At $3.69 each, it was no bargain. I did extensive research and some independant tests of it's effect on aluminum rail and found it not to be a problem. It will discolor fasteners. So three switches and part of the yard is ACQ. The safety issues with this material are no improvement over CCA.

Canadian Hemlock with NO preservativeEven the Hemlock was cheaper than ACQ. Back at $2.69 - ugh. But the local retailer was out of ACQ. So down went the Canadian Hemlock ties. This variety of evergreen has one notable problem -- shake. So toss the ties that have any evidence of shake. Also, there are no natural preservative qualities to this material, so the bugs will bring their knives and forks. The yard tracks are mostly Hemlock. Conclusion: Not Recommended

Behr deck stain.The height of frustration has been reached. I have gone back to hand dipping ties, this time in Behr deck stain. So choose a color you like and stick with it. The Baskin Cutoff is almost entirely deck stained. Conclusion: Not Recommended

Ties that I have NOT used

TimberSilEvidently a silicate based process that is fairly new, relatively inexpensive, and supposedly totally non-toxic. Definately worth looking into for any new construction. Conclusion: Not Recommended

PlasticDefinately worth keeping an eye on. Currently neither cheap to purchase nor ship. I bought a small piece of plastic deck lumber to use as a facing under my barn doors. That one piece was 7 dollars.

ConcreteInexpensive, but very heavy. Do not underestimate the number of trips to the local retailer that will be required because of your vehicle's loading limits. Also consider the amount of labor involved in building and filling forms to make the ties. And, by the way, do not exceed your vehicle's limits whether hauling cement lumber, rail, or even -- trains. Ties on a Budget

Here is an UPDATE Bill

|