Steam Locomotive -- page 19(Back to Page 18) 5/28/6 -- Adding the "Footplate"

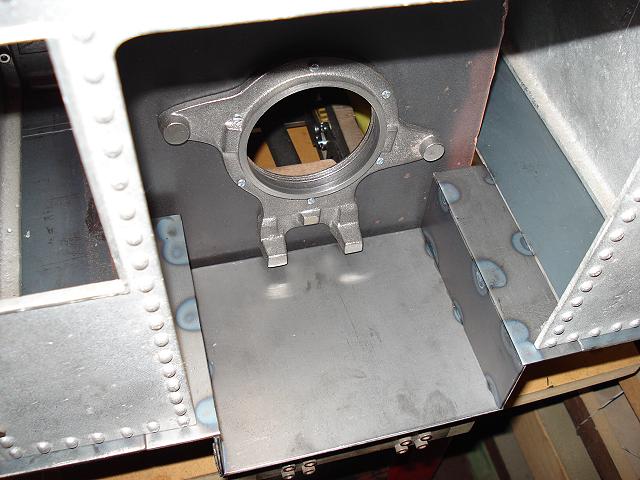

Image 102 -- Cab floor, sidesills and rear walkway extensions Inside the cab, the rear walkways widen, and the cab floor or "foot plate" to those British chaps, drops a good 16 inches below. This is where the engineer and fireman stand (when they are standing). 5/29/6 -- Adding the Underskirt

Image 103 -- Cab Underskirt OK you old-timers: Tell me what this part is really called and I'll change the caption. But for now, I don't know what else to call it. When the engineer, fireman. or hostler climb on board, the steps that they climb are part of the tender. The crew must actually walk between the locomotive and tender. This little wall prevents them from falling under the engine. There are two handrails on each side, one on the tender and one on the locomotive. The locomotive's railings attach to this wall and to the cab. 5/30/6 -- Aligning the boiler

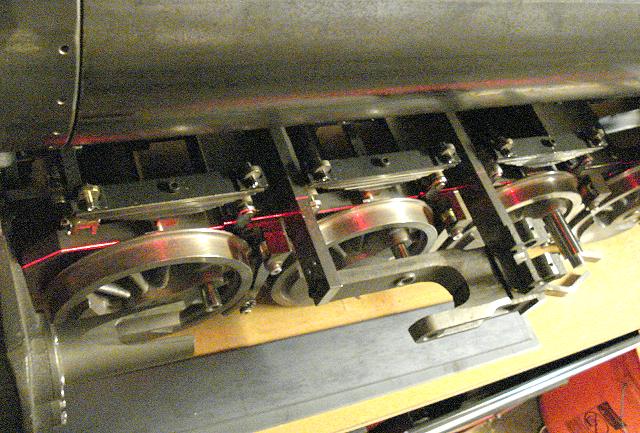

Image 104 -- Using the laser to check boiler alignment Here I've used my Sears Craftsman Laser Level to make sure the boiler lines up with the frame. By projecting the line on the top outside corner of the left frame rail and at the same time have it hit the side of the boiler, I can see that it is lined up. 6/3/6 -- June already here? - More Boiler Work!

Image 105 -- Welding rear walk forward supports to boiler. It's a good idea to do whatever welding needs to be done while you have the boiler off of the locomotive. These walkway supports are a good example.

Image 106 -- Template for smokebox joining ring holes. Here's a computer generated template that tells where to drill the holes for the smokebox/boiler joining ring. Note: This is the same template used to drill the same holes in the smokebox.

Image 107 -- Smokebox joining ring holes drilled. The hole locations are transferred to the boiler using a center punch. Then the holes are drilled. This was done with a hand drill.

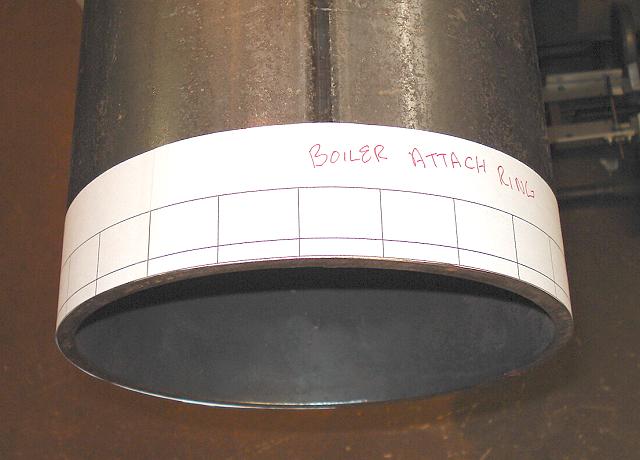

Image 108 -- Getting ready to drill and tap holes in joining ring. Then the joining ring is cut to length, bent, then clamped in place to be drilled and tapped for thr 48 bolts (24 on each side) that will hold the smokebox and boiler together. (On to Page 20) |