90 Ton Mikado, Page 27(Back to Page 26)

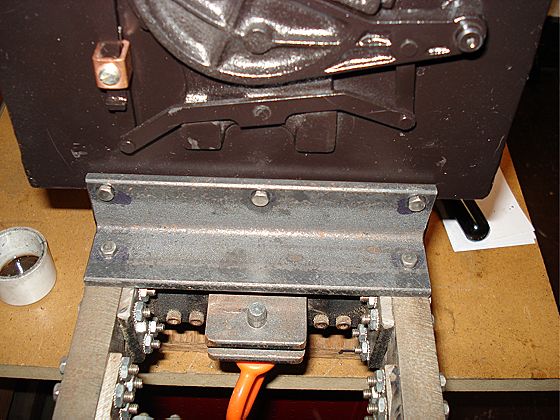

4/1/8 Boiler Supports.

Image 162 -- Rear Boiler Support To make and install the rear boiler support, I had to remove the cab and all the walkways.

Image 163 -- The Black Hole This is looking down the smokebox and boiler. I was doing some work inside, grinding off burs left over from drilling and tapping screw holes. You can see the joining ring in operation.

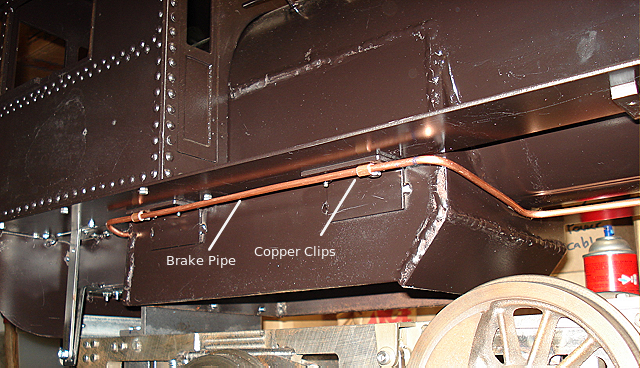

4/5/8 Brake Pipe and Rear Cab SupportI made a bunch of 3/16" tubing clamps out of 1/2" copper pipe, cut into strips. Then I ran a tube from the brake valve along and underneath the right walkway and along the underside of the boiler to a union connecting the frameside brake pipe. I used 2 of the new clamps to support the pipe. I will probably soon take these clamps back off and expand them to 5/16" and add a short piece of teflon tubing to each to reduce heat loss.

Image 164 -- Brake Pipe and Clamps

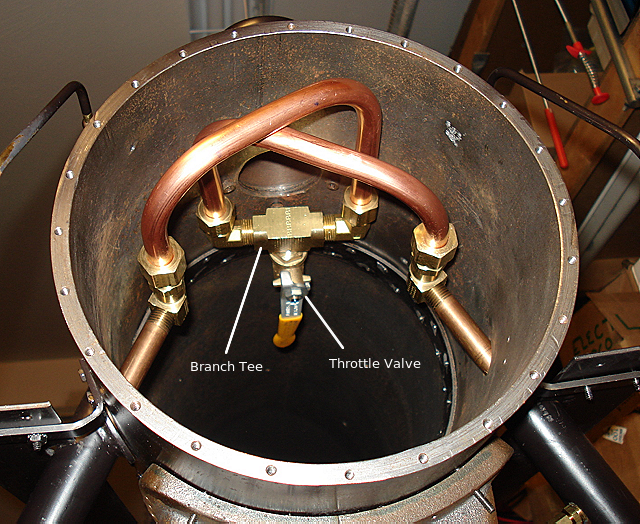

4/8/8 - Branch Pipes inside the smokeboxYou've seen the branch pipes outside the smokebox. but what happens inside? They need to be joined to the branch tee and the throttle valve. But that is hard to do inside the limited space of the smokebox. For one thing, fittings need to be threaded on to the pipes, and one final connection cannot be threaded on. Plus, the branch pipes come in at an odd angle (29 degrees). Unions are expensive and do not allow for an adjustable fit.

Image 166 -- Throttle Valve and Branch Tee My solution is to use compression fittings for the final connections and have all of them facing forward for easy assembly and disassembly. The branch pipes enter the smokebox and make a right angle bend (face forward) via a street elbow and a compression tube adapter. The branch tee is fitted with right angle compression tube adapters (also face forward). The final connections are made with U-shaped pieces of tubing. The crossing of the tubes is necessary because the distance between the branch tee to the branch pipe on a given side is less than three inches and that is the minimum 180 degree bend for my tubing bender on 1/2" OD tubing. By crossing over, I eliminate that problem. Plus a little extra tubing inside the smokebox isn't going to hurt. A little steam superheating isn't going to hurt either. It is important to keep the flow from these tubes downhill so that water can't collect in them. Notice how the tee and tubing avoids the stack. Not shown is the exhaust tube which must rise between them. Also not shown is the feedwater heater coil, which will soon be built.

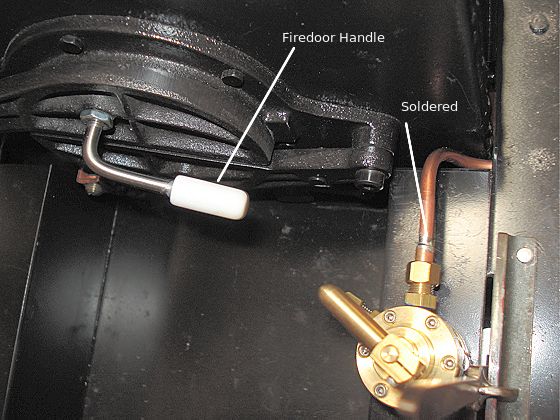

4/11/8 - Firedoor Handle

Image 167 -- Firedoor Handle One of those "do it anytime" items is the firedoor handle. Retrospectively, it should have been done at the same time the firedoor was built. The handle has a ceramic "grip" to make it touchable when hot. I also soldered the brake pipe to it's fitting. (On to Page 28) |