90 Ton Mikado, Page 28(Back to Page 27)

4/12/8 - Reverse Rod + Numberboards

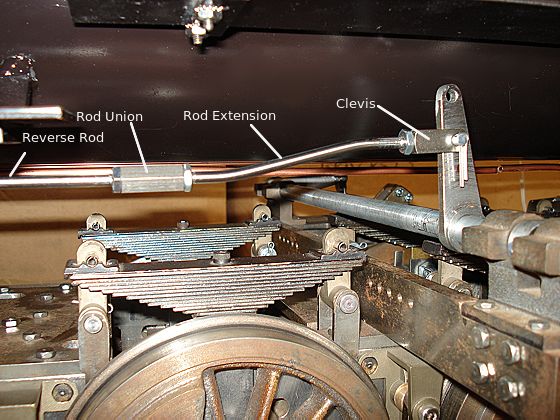

Image 168 -- Reverse Rod and Linkages This is my second try on the reverse rod. The first time I had too many clevises which caused too much slack in the linkage. I still use a 2-piece rod, but now the coupling is rigid.

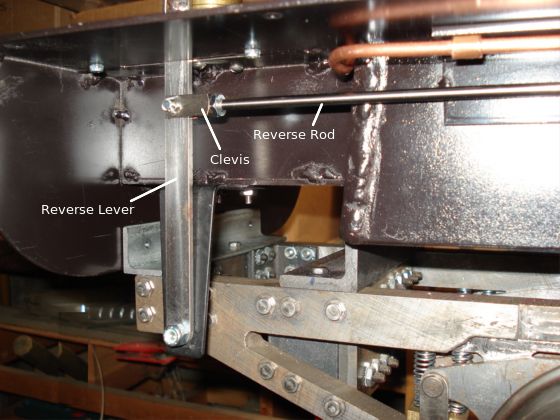

Image 169 -- Reverse Rod and Linkages

Image 170 -- Number Boards I bought some high temperature glass to make numberboards with. (With a 55 watt halogen bulb in the headlight, it gets rather toasty.) When the glass arrived I noticed the edges were quite sharp, so I started looking for something to frame the glass with. In searching the internet for "brass channel" I noticed that "brass came" was also returned in my search results. Never heard of it. But curiously, I decided to find out what it was. Come to find it is very inexpensive and sold by stained glass companies for the purpose of framing cut glass. It works great for number boards.

7/18/8 - Angled Boiler Supports

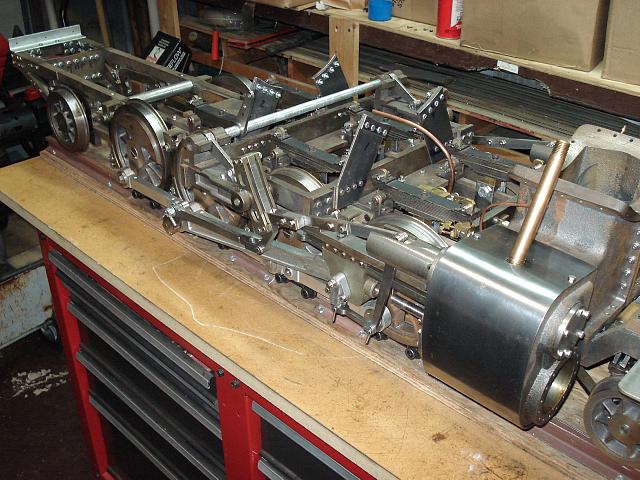

Image 171 -- Left side boiler supports and weld tabs Something I've put off for a long time - Angled Boiler Supports. This is a trim and fit part. The drawings just give a general idea what they should look like and it's up to the builder to make it fit.

Image 172 -- Right side boiler supports and weld tabs Notice the "weld tabs". These are at the upper end of each angled support and bearing the same shape. These weld directly to the boiler and still allow me to separate them from the supports. No they are not yet welded on. Also, notice: I have moved my work bench. I can now work on both sides of the model. Why didn't I think of that 5 years ago?

8/2/8 - Cylinder Wrappers

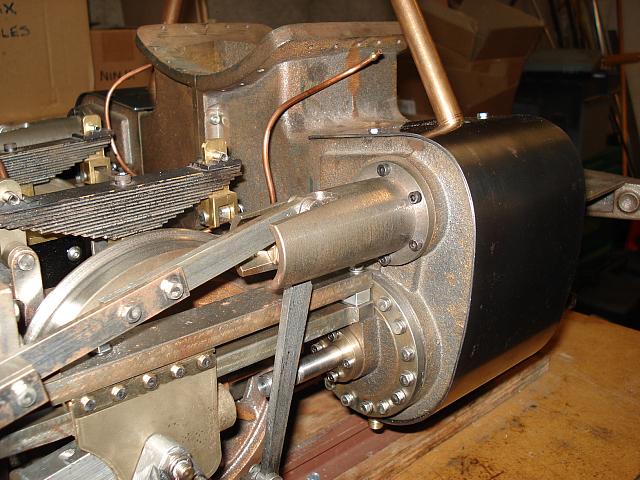

Image 173 -- Chassis with Boiler Supports and Wrappers Now here's a really tough part to make (for me). For one thing, I have absolutely no tools for bending sheet metal, the set of drawings does not even mention this part, and it's 16 gauge cold-rolled steel.

Image 174 -- Cylinder Wrappers I used one of the floor support posts in my basement as a form for the main cylinder end, and once in place used the cylinder assembly itself as a form for the rest of the bending. I also used two 2x2 wood strips in the vise as an additional bender.

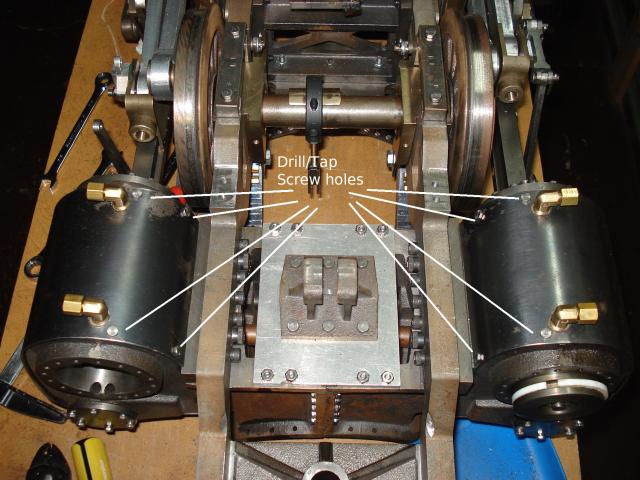

Image 175 -- Cylinder Wrappers - drilling and tapping bottom holes It seems that few know about the importance of this part. The cylinders are supposed to be insulated to reduce steam condensation. The wrappers cover the (asbestos) insulation. I didn't have any asbestos, so I wrapped them as best as I could. (On to Page 29)

|