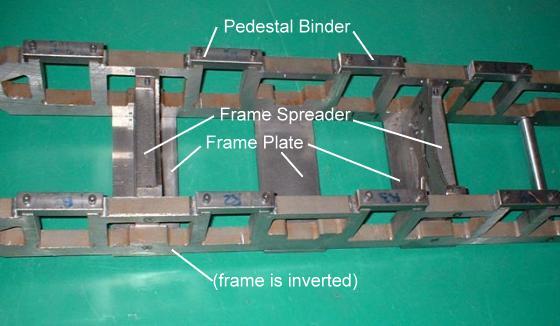

Steam Locomotive, Page 3(Back to Page 2) 5/11/2 Now it's on to building the frame. Even though the side-frames are water-jet cut, there are several dimensions that must be precisely machined, and many many holes that must be drilled. Some of the frame components are included in the castings kit, and must be machined to the correct dimensions. These include the frame spreaders (shown below), the pilot beam, and the front deck. Other parts you must make yourself, such as the pedestal binders and the frame plates (also shown).

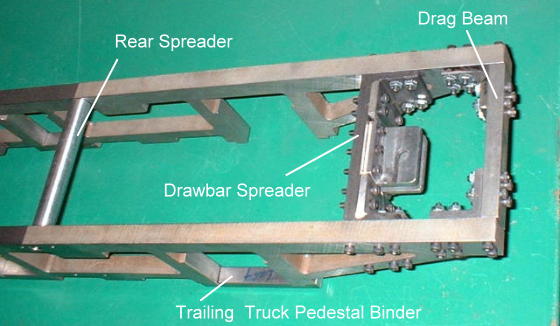

Image 7. Frame, spreaders, plates, and binders The rear spreader is just a piece of unthreaded rod salvaged from my son's go-cart. The drawbar beam holds the drawbar attachment brackets, which attaches to the tender's drawbar and pulls the train. The drag beam is the rear end of the frame

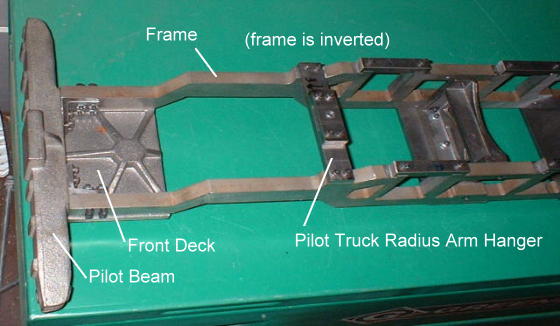

Image 8. Rear spreader, Drawbar beam, and Drag beam At the front of the engine are two large castings. One is the "pilot beam", which carries the front coupler and some sort of pilot or "Cow Catcher". The second is known as the "front deck" which carries the bearing for the pilot truck yoke. In this photo, the hole for the yoke is not drilled yet. Parts, such as the pilot beam mounting brackets, the pilot truck radius arm hanger, the radius arm keeper, frame plates, and pedestal binders must be made by the builder using flat and angle stock.

Image 9: Pilot beam, Front Deck, Pilot truck radius arm hanger (On to Page 4) |