Jump to Page 2

Jump to Page 3

Visit Powered Tender Truck page

-

Image 1 - Completed Tender

This tender consists of two parts. - The tank, and the coal chute.

The tank will carry water for the boiler. The coal chute will carry fuel,

a battery for the headlight, bell motor, cab lights, and train brakes

and will serve as the engineer's seat.

The tank is an off-the-shelf 11 gallon air tank with the handle, feet, and

hose attachments removed. The chute is made from 1/8th inch steel plate

stock.

The following is a description of the components of the coal chute.

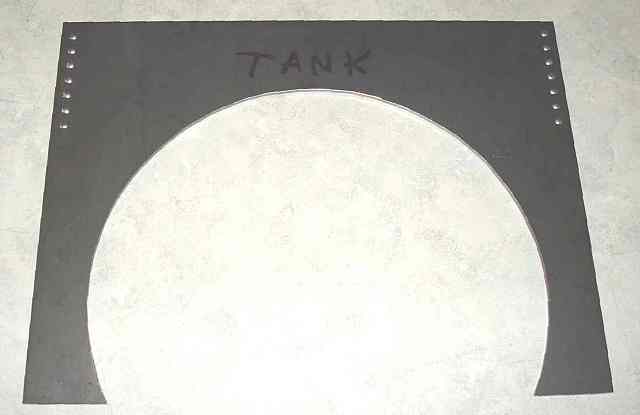

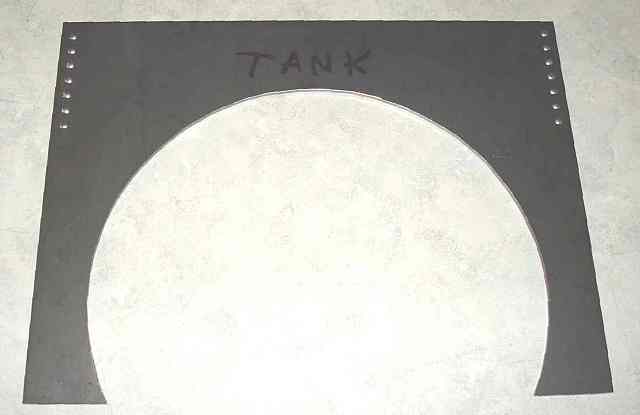

Rear Wall

-

Image 2 - The Rear Wall

The upper rear wall of the coal chute welds directly to the tank. It also

welds to the wing walls as well as the walkways that extend along the

tank. (You will see these parts described later.)

-

Image 3 - Rear Wall to Tank Location

Here, the rear wall is in position on the tank. Some of the paint must

be ground away before welding.

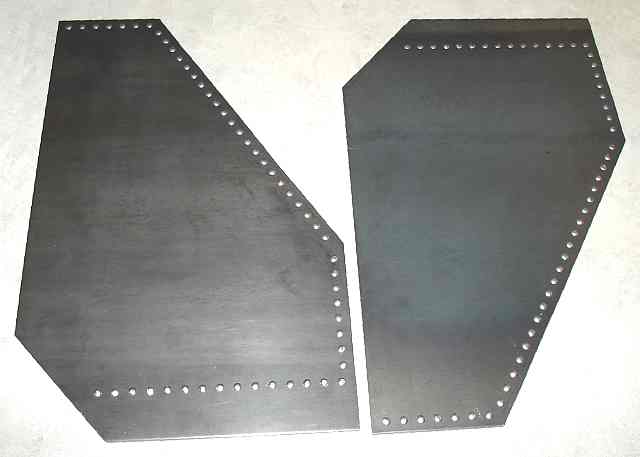

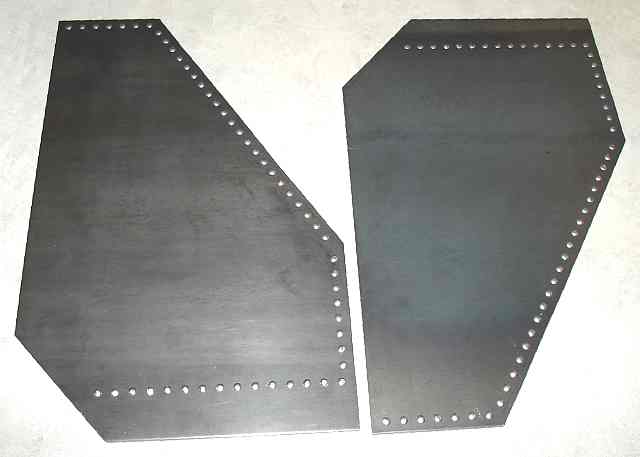

Wing Walls

-

Image 3 - The Wing Walls

Called wing walls (by me and not the rail industry) because of their shape.

In reality, these are the left and right side walls of the coal chute. They

weld directly to the upper rear wall, the coal chute itself, and the front

wall.

Foot Walls

-

Image 4 - The Foot Walls

The foot walls support the coal chute. They weld directly to the front wall,

the upper and lower rear walls, the floor, and the coal chute.

Front Wall

-

Image 5 - The Front Wall

The front wall faces the locomotive. Ordinarily it would have doors that

would open to the coal chute. I have chosen to leave it as a solid piece

since I don't need access to the bunker on that side. It welds directly to

the foot walls, wing walls, and the bunker floor.

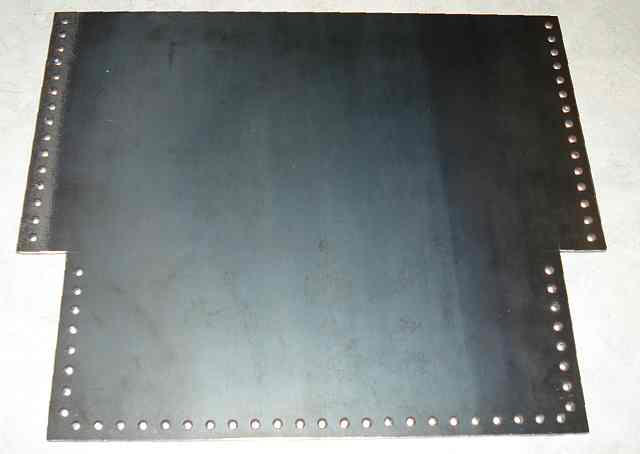

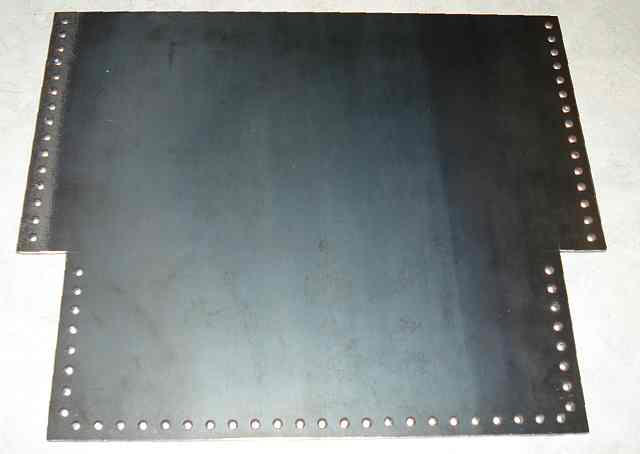

Bunker Floor

-

Image 6 - The Bunker Floor

The floor of the coal bunker is the largest single part of the coal bunker.

It welds directly to the foot walls, the front wall and to the lower

rear wall.

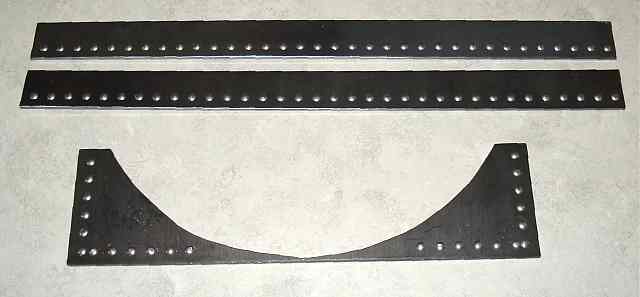

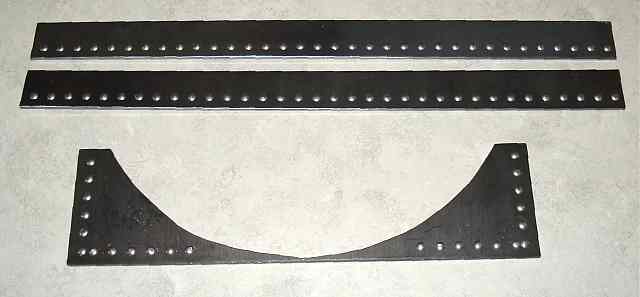

Lower Rear Wall

and Coal Chute (sort of)

-

Image 7 - Bunker Rear Wall and Chute Floor

The coal chute has an angled floor, sloped from the back to near the center

of the coal tipple and a horizontal floor the rest of the way to the front.

Ordinary, the chute would extend the width of the tipple. In my case, it is

no wider that the distance from the wing walls to the feet. This creates a

larger storage area for fuel, batteries, pumps, and a compressor, underneath

what will be the engineers seat.

The strips at the top of this photo are what's left of the coal chute. At

the bottom is the lower part of the rear coal bunker wall. This also welds

directly to the tank.

Onward to Page 2

Jump to Page 3

Visit Powered Tender Truck page

|